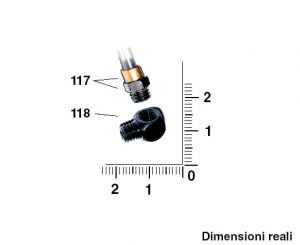

Resistive dosing valves for low pressure 0,75-1-2-4-8-16 drops per minute 2-3-4-5-6 ways line distibutors/dividers 3 ways line divider Volumetric dosing valves for medium pressure 0,03-0,05-0,07-0,10-0,15-0,20-0,25-0,30 cm3 Straight terminal connection M 3×0,5 M 6×1,0 M 8×1,0 M 10×1,0 and 1/8”G 90° terminal connection M 3×0,5 M 6×1,0 M 8×1,0 M 10×1,0 and 1/8”G.

PRODUCTS

DISTRIBUTORS – DOSING VALVES – CONNECTIONS

Distributors

Distributor obtained from coaxial perforated extruded aluminium bars. Each model has the line inlet and outlet at the ends and two holes for fixing to a wall. They are available with from 2 to 6 radial ways with a pitch of 14 mm. The identification code refers to the number of radial ways excluding the inlet and outlet.

Distributor obtained from drawn aluminium bars. Each model has the line inlet and outlet at the ends and two holes for fixing to a wall. They are available with from 2 to 6 radial ways with a pitch of 19 mm.

The identification code refers to the number of radial ways excluding the inlet and outlet.

Dosing Valves

The resistive dosing valve, under low pressure, has its flow rate determined in drops per minute, the volume of a drop corresponds to 33 mm3, the quantity of drops is defined as the relative flow rate. The range of relative flow rates is given in the table. The relative flow rate is determined with the following parameters: oil with a viscosity of 65,5 cSt at 40°C, test temperature 20°C, mean test pressure 2,7 bar. Modifying even just one of these parameters varies the relative flow rate.

The “Z Series” fixed flow-rate volumetric dosing valve is characterized by the fact that at the lubricant inlet there is a special valve, patented for Italy, USA, Germany, Mexico, Canada and Saudi Arabia, and in the general construction context it is distinguished by having a double seal in the two phases of Work and Pause. It can thus be defined a medium pressure fixed flow-rate “Double Seal Volumetric Dosing valve.”

The “L Series” fixed flow-rate volumetric dosing valve differs from the “Z Series” volumetric dosing valve in its compactness, reduced sized, direct locking of the pipe Ø4 for the service. Like the “Z Series,” it is characterized by the fact that at the lubricant inlet there is a special valve, patented for Italy, USA, Germany, Mexico, Canada and Saudi Arabia, and in the general construction context it is distinguished by having a double seal in the two phases of Work and Pause.

Accessories

The FL BP.81 filter is composed of a body and an aluminium cap, screwed together and a wall bracket. On the inside there is a star cartridge with a seal and paper filtering element, with filtration 10-30 mm.

The FL BP.81 model is not fitted with a one-way check valve as all our low pressure pumps are equipped with this type of valve, it must not be installed in systems with pumps with a line pressure release valve.

The FL MPBY.18 filter is composed of a top body with a By-pass valve on the outlet duct and an aluminium cap, screwed together. Wall fastening with bracket. On the inside there is a star cartridge with a seal and paper filtering element, with filtration 10-30 mm.

In the top cap there is a By-pass valve on the outlet/service duct with two opposing one-way check valves to prevent oil returning into the cartridge and particles of dirt separating from the filtering surface in the phase of decompression of the main line for recharging volumetric dosing valves.

Rubber hoses joint

at the two ends.

Sae 100 r7 nylon hoses.

Neutral rilsan pipes.

Stop bushings.

Stop nuts.